In modern architecture, the pursuit of more dynamic and organic shapes demands flexible, precise, and high-performance construction solutions. The KingZip system meets this need by offering an advanced solution for executing curved and three-dimensional envelopes using high-quality standing seam trays.

On-site Manufacturing for Limitless Projects

One of KingZip’s main advantages is its on-site manufacturing capability, thanks to mobile production units that are transported directly to the construction site. This allows for the production of trays from 1 to 150 meters in length, adapting to all types of projects—even those requiring complex and continuous geometries

Wide Range of Applications and Finishes

The KingZip system is ideal for creating architectural envelopes in industrial, residential, commercial buildings and sports facilities. It is available in both steel and aluminum, with a variety of finish options that allow for customized design tailored to the aesthetic and functional needs of each project.

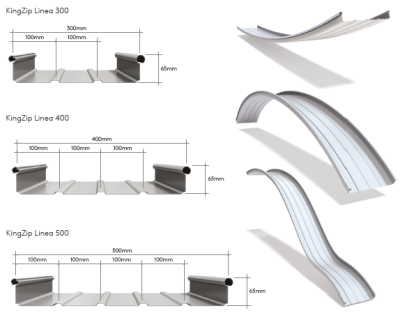

KingZip Line: Technical Precision in Every Detail

Within the system, KingZip Linea stands out—a tray with a constant width, available in three sizes: 300, 400, and 500 mm. This solution is perfect for constructing envelopes with angular, convex, concave, or conical shapes, always with high technical precision and impeccable aesthetics. Learn more about KingZip